What is Natural Proteoglycan

The miracle compound

Natural Proteoglycan

With the world's only technique LPT, proteoglycan has been dramatically improved proteoglycan has been dramatically improved

As an ingredient that approaches cells themselves to work on fundamental causes of every kind of disorders, proteoglycan is

noted in various fields as healthcare foods, cosmetics and other medical care industries.

It has become noticed after the extraction technique has been developed in Japan in 2003, which has enabled its mass production.

After that continuous efforts by researchers have been made to improve the technique more and more, which has finally enabled mass production of proteoglycan in higher purity without losing any of its functionality.

This is the brief story how proteoglycan has been produced.

This page of this website will show you its huge possibility based on an interview to Yoshiaki Kudo, the parent of proteoglycan who has established LPT (Leave Protein Technology) , the world’s only technique by developing an innovative technique.

Yoshiaki Kudo

President and CEO of Biomatec Japan, Inc.

Born on 28 April, 1942 in Aomori pref,Japan.

Graduated from Sapporo West High School and Waseda University (political science and economic department)

Worked for Kakuhiro Corporation from 1972.

Started his study of proteoglycan at the planning and development section of the same company from 1998.

Continued his study in their research laboratory in Kushiro from 2002, but resigned this company in 2005 at the timing of their withdrawing of operations.

Kept working on his study on his own and found a new extraction technique of proteoglycan in November, 2005 and acquired its patent.

Founded Biomatec Japan in May, 2006.

*This page is composed based on an interview to Mr. Yoshiaki Kudo as well as his lectures or research documents.

History of Mr. Yoshiaki Kudo

and the development on natural proteoglycan

July, 1998

As an employee of Kakuhiro Corporation, started studying on mass production of proteoglycan in collaboration with Hirosaki University

March, 2003

Established a mass production technique by extracting proteoglycan out of salmon nasal cartilages

February, 2005

Resigned Kakuhiro Corporation at the timing of their withdrawing of operations and started his own study on original extraction technique

May, 2006

Founded Biomatec Japan, Inc.

Contracted on a joint study with the Kushiro Industrial Technology Center

November, 2006

Contracted on a joint study with Hokkaido University

February, 2007

Applied to an international patent

June, 2007 Passed the cosmetics safety test

August, 2007

Adopted the Regional resource utilization type Research and Development Project, the METI commissioned project

October, 2008

Being approved the Japanese patent No.4219974

December, 2008

Received a thank-you letter from the governor of Hokkaido for the cooperation to the Hokkaido Toyako Summit

June, 2009

Adopted the Practical technology development projects to promote the new Agriculture, Forestry and Fisheries Policy, the

MAFF commissioned project

November, 2009

Won the Hokkaido New Technology and New Product Development Award, the Monodzukuri Section Encouragement Award

October, 2010

Being approved the Russian patent No.2401839

September, 2011

Acquired the HALAL certification

February, 2012 Won the Monozukuri Nippon Grand Award “Prime Minister’s Award

April, 2012

Being approved the US patent No.8153769

May, 2012

Gave a lecture on the possibility of proteoglycan at the Sapporo Stock Exchange

October, 2012

Won the Encouragement Award of Small and Medium Enterprise at the prize-giving ceremony 2012 by the Institute of Invention

October, 2012

Proteoglycan exhibited in the 2012 annual meeting of IMF, the government-sponsored exhibition, nominated by the Ministry of Finance

November, 2012

Televised by NHK in a nation-wide network program

Mr. Kudo speaks on

what is natural proteoglycan

The development process and its superiority

The world-first mass production of acetic acid

The process to practically apply proteoglycan

Study on structure or bioactivities of proteoglycan had been continued since 1970s, which had been greatly expected its application to medical and pharmaceutical products, health foods and cosmetics.

However, no effective extraction technique having been established as well as its selling price being very expensive to be more than 30 million yen per gram, it was quite unreasonable to use for consumer products.

At the end of 20c, the research team led by Professor Keiichi Takagaki from Hirosaki University had finally resolved this difficult problem.

In 1998, a joint project to develop a mass production technique of proteoglycan was proposed by Hirosaki University to Kakuhiro Corporation which I had been working for at that time, and I was chosen to the person in charge of that project.

Though I was a complete beginner in medical field, I started studying in Hirosaki University medical department at the age of 55 to learn proteoglycan from nothing.

I have learned that biological activities by all the animals including human beings are supported by proteoglycan from the back, which plays a significant role for their health.

So artificially mass producing it will be so much valuable, with which interested me much as I was sure that it will greatly contribute to medical field.

And finally in 2003, I was successful in finding a mass production technique of proteoglycan by acetic acid extraction, being researched with Professor Takagaki from Hirosaki University and others.

Thanks to that I could have realized a breakthrough pricing as 300 thousand yen per gram.

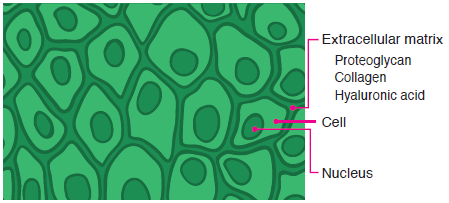

■Proteoglycan to govern extracellular matrix

Between the cells there is a jelly like substance which is called extracellular matrix.

Common ingredients that compose this extracellular matrix are hyaluronic acid and collagen, but it has revealed that proteoglycan is the most important ingredient between them.

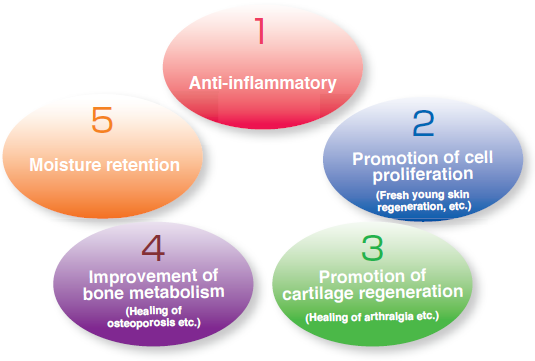

Not only high moisture retention, it brings about promotion of skin regeneration (same effect as EGF) by generating additional collagen and hyaluronic acid.

■The revealed physiological function of proteoglycan

Proteoglycan is disconnected on the way?

Difficulties in cost and technical challenges

Cost reduction from 30 million yen ($270,000)per gram to 300 thousand yen ($2,700) per gram is a really wonderful result.

I have visited health food and cosmetic companies across Japan by flying more than 100 times a year with samples of proteoglycan.

Everybody in charge of technology or product development was greatly interested in it, but no managements said yes, as for manufacturers the reasonable price is 1,000 yen (=US$9) per gram (=0.035oz) to use it for their merchandises.

They said that even 300 thousand yen (=US$2,700) per gram is too expensive.

February 2005, Kakuhiro Corporation has decided their withdrawal from proteoglycan business as they could have got no order even after investing much money on its development.

But I could not give up realizing mass production of proteoglycan as my dream.

I'm approaching the goal. Proteoglycan is sure to be essential for human body so its mass production is useful for people and society.

This was my belief that made me resign this company and decide to keep studying on the research on my own.

This was a starting up at the age of 64. There was another challenge to clear other than to realize the almost impossible pricing as 1,000 yen (=US$9) per gram.

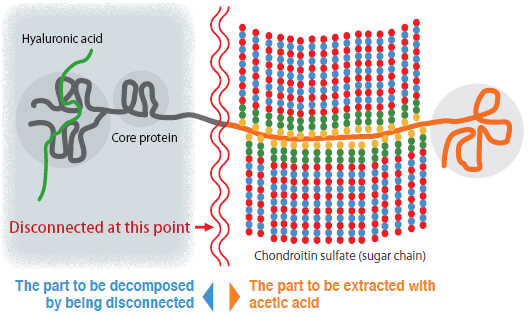

With the acetic acid extraction method developed by Hirosaki University, core protein of proteoglycan could not avoid to be disconnected on the way thus hyaluronic acid was not to be combined.

So we could have been successful in extracting the crude natural proteoglycan, which was the most difficult challenge to resolve.

■Decomposition of proteoglycan by acetic acid extraction

■Hyaluronic acid is not to be combined!

Moisture retention ability that represents proteoglycan is raised by being combined with hyaluronic acid, so the moisture retention effect will be spoiled when this combined part is lacking.

The solution was alkaline extraction

Natural and pure proteoglycan

After having become independent in 2005, I have started my own study on mass production of proteoglycan by using all of my property.

To make the pricing into 1/300 and to exract proteoglycan in a natural form as it is without being decomposed by disconnection of core protein, I have tried everything that I could think of and repeated experiments day after day.

In the end I could reach at a method which is totally opposite method to the acetic acid extraction, the alkaline extraction.

I was not in pursuit of the theory itself.

All the researchers were thinking then that nobody would use caustic soda when to protect protein.

But I had an intuition that it would be successful in some way.

Caustic soda is inexpensive and it will not disconnect core protein in proteoglycan, but the requirement is quite severe.

If the factors as temperature, concentration and time are changed even slightly, its extraction rate would change a lot.

So I had to repeat experiments more than 1,000 times.

The budget was nearly to be used up, and I was just thinking of giving it up if I could not be successful in that last experiment, where the miracle occurred.

I had finally found an ideal extraction method of proteoglycan that I had long pursued for, which to keep its purity at 90% and above, its price at less than 1,000 yen per gram, not to be disconnected on the way.

Soon after this miracle happened, I had named this proteoglycan as natural proteoglycan and applied for patent.

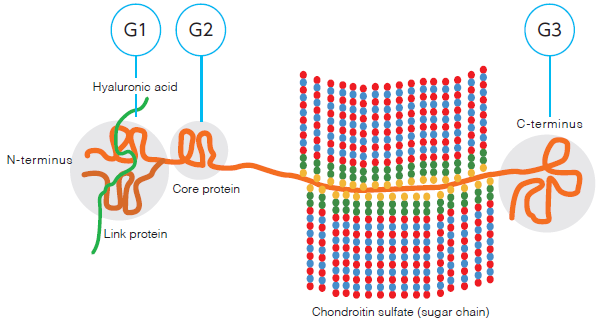

■Structure and functionality of natural proteoglycan

Hyaluronic acid binding region

To raise its moisture retention by combining with hyaluronic acid with link protein

Function unidentified region

A region whose function is not clarified yet

EGF-like region

To show a wound healing effect same as EGF.

And to work as hyaluronic acid production promoter, collagen degradation accelerator and collagen synthesis inhibitor at the same time.

Establishment of LPT (Leave Protein Technology)

Purity 90% and above, a miracle compound

I was so lucky enough to establish LPT (Leave Protein Technology) by alkaline extraction only after 6 months from starting to study on my own while there are tons of scientists who reach their goal throughout their lifetimes.

Natural proteoglycan got into the news and won many big honors as the Monozukuri Nippon Grand Award "Prime Minister's Award".

As you may know, human body consists of cells and they are supported by the extracellular matrix.

And the most important worker of them all is proteoglycan.

To broadly send it out into the world is to contribute to medical science as well as human healthcare.

But still, there are so many poor-quality ingredients that are named as proteoglycan.

One with additional agents such as digestion resistant dextrin or cartilage glint into powder are even named as proteoglycan to be used in health foods or cosmetics.

Their quantity written on the package is nothing to be relied on.

In such a society, it’s not yet a good timing for me to retire.

I commit to keep developing crude natural ingredients not only proteoglycan but other useful ones to activate self-healing power of human beings.

In 2012, I won the Monozukuri Nippon Grand Award “Prime Minister’s Award”.

I was at the award ceremony and was given a chance to give explanation about proteoglycan to the then prime minister Mr. Noda at the prime minister’s official residence.

The Biomatec Japan company office building at the Kushiro industrial park in Kushiro, which was newly completed in July, 2015

Are you interested in Proteoglycans?

If you want to get it, visit this page.